Apakah kaedah yang digunakan untuk menggunakan salutan PVC pada fabrik asas?

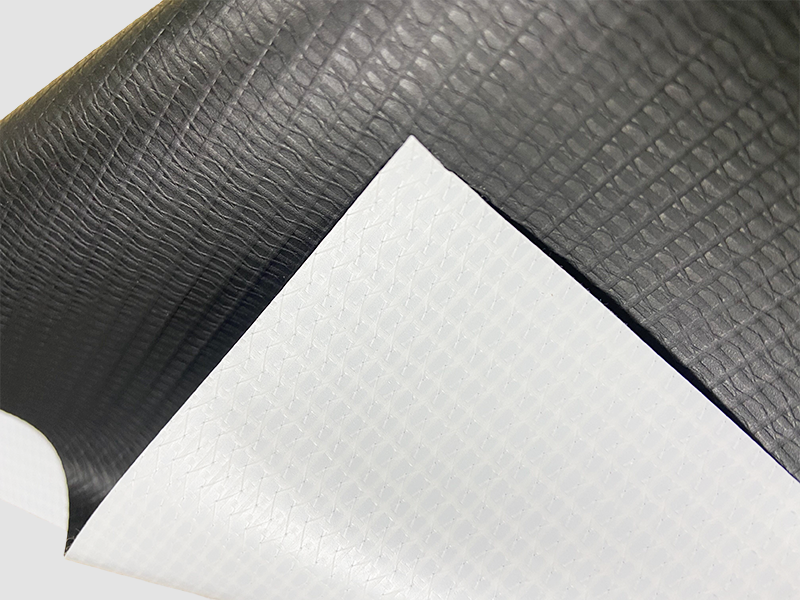

Salutan PVC biasanya digunakan pada fabrik asas

Fabrik Khemah Tegangan PVC menggunakan salah satu daripada beberapa kaedah biasa. Kaedah ini memastikan lekatan yang betul dan litupan seragam salutan PVC pada substrat fabrik. Beberapa kaedah yang paling biasa digunakan termasuk:

Salutan Pisau: Dalam salutan pisau, pes atau cecair PVC digunakan pada permukaan kain asas menggunakan aplikator seperti pisau. Kain melepasi di bawah pisau, yang menyebarkan salutan PVC secara merata ke seluruh permukaannya. Ketebalan salutan boleh dilaraskan dengan mengawal jurang antara pisau dan fabrik. Selepas salutan, fabrik melalui proses pengawetan atau pengeringan untuk menguatkan salutan PVC.

Salutan Celup: Salutan Celup melibatkan merendam fabrik asas ke dalam tangki atau tong yang diisi dengan penyebaran atau larutan PVC. Fabrik disalurkan melalui tab mandi salutan, membolehkan salutan PVC menembusi gentian fabrik dan melekat pada permukaan. Salutan berlebihan biasanya dikeluarkan dengan menyalurkan fabrik melalui penggelek pemerah atau bilah doktor sebelum menjalani proses pengeringan atau pengawetan untuk mengukuhkan salutan PVC.

Kalender: Kalender ialah proses mekanikal yang melibatkan penghantaran fabrik asas dan tampal PVC atau sebatian melalui satu siri penggelek yang dipanaskan. Penggelek memampatkan dan meregangkan salutan PVC, memaksanya ke dalam gentian fabrik dan membentuk lapisan nipis dan seragam pada permukaan. Kalender boleh digunakan untuk menghasilkan fabrik khemah PVC dengan ketebalan yang tepat dan kemasan permukaan yang licin.

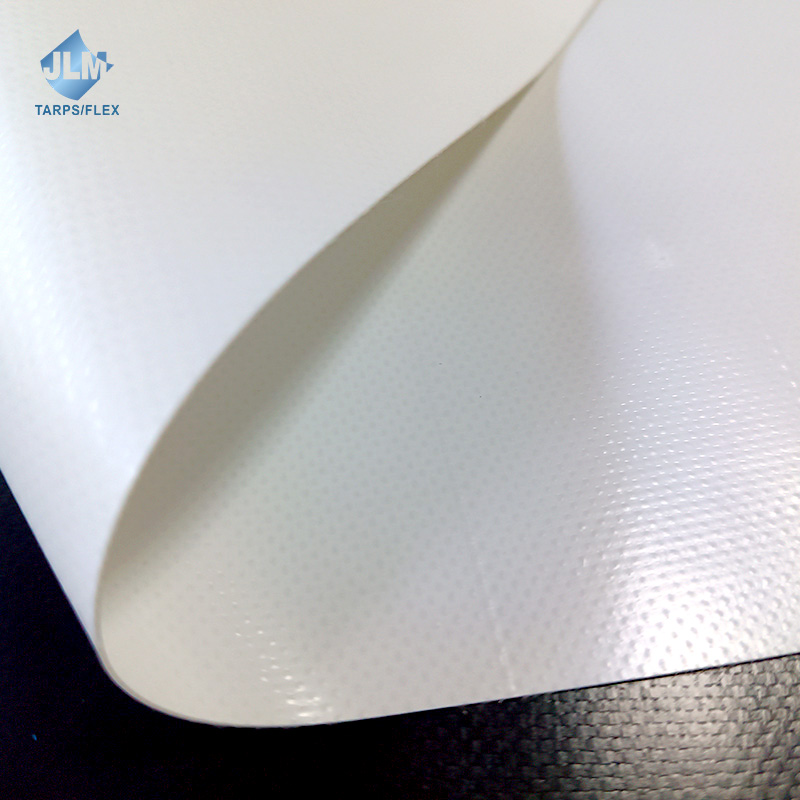

Salutan Penyemperitan: Salutan penyemperitan ialah proses berterusan di mana resin PVC cair diekstrusi melalui acuan ke atas permukaan fabrik asas. Fabrik melepasi di bawah acuan penyemperitan, dan PVC cair membentuk salutan apabila ia menyejuk dan memejal apabila bersentuhan dengan fabrik. Salutan penyemperitan sering digunakan untuk menghasilkan fabrik khemah PVC dengan salutan kalis air dan tahan lama.

Salutan Semburan: Salutan semburan melibatkan penyemburan penyebaran atau larutan PVC ke permukaan kain asas menggunakan muncung semburan atau pistol. Salutan PVC diatomkan menjadi titisan halus, yang didepositkan ke permukaan kain untuk membentuk lapisan seragam. Salutan semburan membolehkan kawalan tepat ke atas ketebalan dan liputan salutan dan sesuai untuk menghasilkan fabrik khemah PVC dengan kemasan atau corak khusus.

Kaedah ini mungkin berbeza bergantung pada faktor seperti ketebalan dan sifat salutan PVC yang dikehendaki, jenis fabrik asas yang digunakan dan keperluan khusus aplikasi. Setiap kaedah mempunyai kelebihan dan batasannya dari segi kos, kecekapan, dan kualiti fabrik khemah PVC akhir yang dihasilkan.

Bolehkah ia digunakan untuk tujuan komersial dan kediaman?

Kain khemah PVC boleh digunakan untuk tujuan komersil dan kediaman kerana sifat serba boleh, ketahanan dan tahan cuaca. Begini cara ia boleh digunakan dalam setiap konteks:

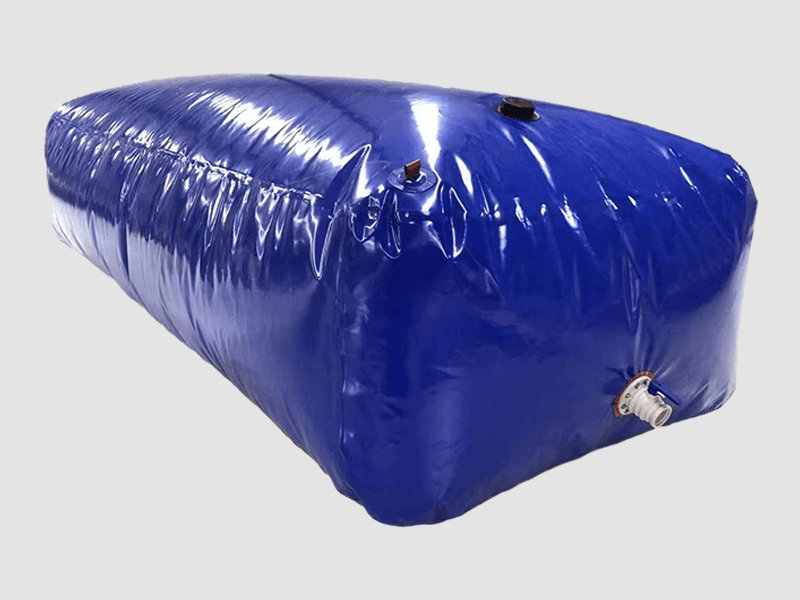

Tujuan Komersial: Khemah Acara: Fabrik khemah PVC biasanya digunakan untuk khemah acara komersial, seperti yang digunakan untuk majlis perkahwinan, pameran perdagangan, perayaan dan acara korporat. Khemah-khemah ini menyediakan tempat berteduh sementara dan boleh menampung perhimpunan ramai orang. Fabrik khemah PVC menawarkan perlindungan cuaca yang sangat baik, membolehkan acara diteruskan walaupun dalam keadaan cuaca buruk.

Industri Hospitaliti: Dalam industri hospitaliti,

Bahan Tarpaulin Khemah PVC digunakan untuk mencipta ruang makan luar, ruang istirahat dan kemudahan rekreasi untuk hotel, pusat peranginan dan restoran. Struktur ini menyediakan tetamu dengan ruang luar yang selesa dan berfungsi sambil melengkapkan estetika dan suasana hartanah.

Kanopi Komersial: Fabrik khemah PVC digunakan untuk membina kanopi komersial dan struktur teduh untuk perniagaan, seperti ruang tempat duduk luar untuk kafe, kedai runcit, pengedar kereta dan kemudahan rekreasi. Struktur ini menawarkan perlindungan daripada matahari, hujan dan angin sambil meningkatkan daya tarikan visual harta itu.

Tujuan Kediaman: Khemah Kediaman: Fabrik khemah PVC boleh digunakan untuk mencipta khemah kediaman atau struktur sementara untuk acara belakang rumah, perjalanan perkhemahan dan aktiviti rekreasi. Khemah-khemah ini menawarkan kepada pemilik rumah penyelesaian tempat perlindungan yang serba boleh dan mudah alih untuk menganjurkan perhimpunan luar, barbeku belakang rumah atau bersantai di taman.

Penutup Patio: Fabrik khemah PVC digunakan untuk membina penutup teres, pergola dan layar teduh untuk hartanah kediaman. Struktur ini memberikan naungan dan perlindungan daripada unsur-unsur, membolehkan pemilik rumah menikmati ruang kediaman luar mereka sepanjang tahun.

Bahan Khemah PVC menawarkan pilihan reka bentuk yang boleh disesuaikan untuk melengkapkan gaya seni bina rumah dan meningkatkan estetika luaran.

Penutup Kolam: Fabrik khemah PVC boleh digunakan untuk membuat kepungan kolam dan bilik matahari untuk kolam renang kediaman. Kandang ini menawarkan perlindungan daripada serpihan, serangga dan sinaran UV yang keras sambil memanjangkan musim berenang dan menyediakan persekitaran yang selesa untuk bersantai dan beriadah.

Sama ada untuk tujuan komersil atau kediaman, fabrik khemah PVC menawarkan penyelesaian yang kos efektif, tahan lama dan boleh disesuaikan untuk mencipta struktur perlindungan sementara atau kekal yang memenuhi keperluan dan pilihan pengguna. Fleksibiliti, rintangan cuaca dan kemudahan pemasangan menjadikannya pilihan ideal untuk pelbagai aplikasi dalam kedua-dua tetapan.